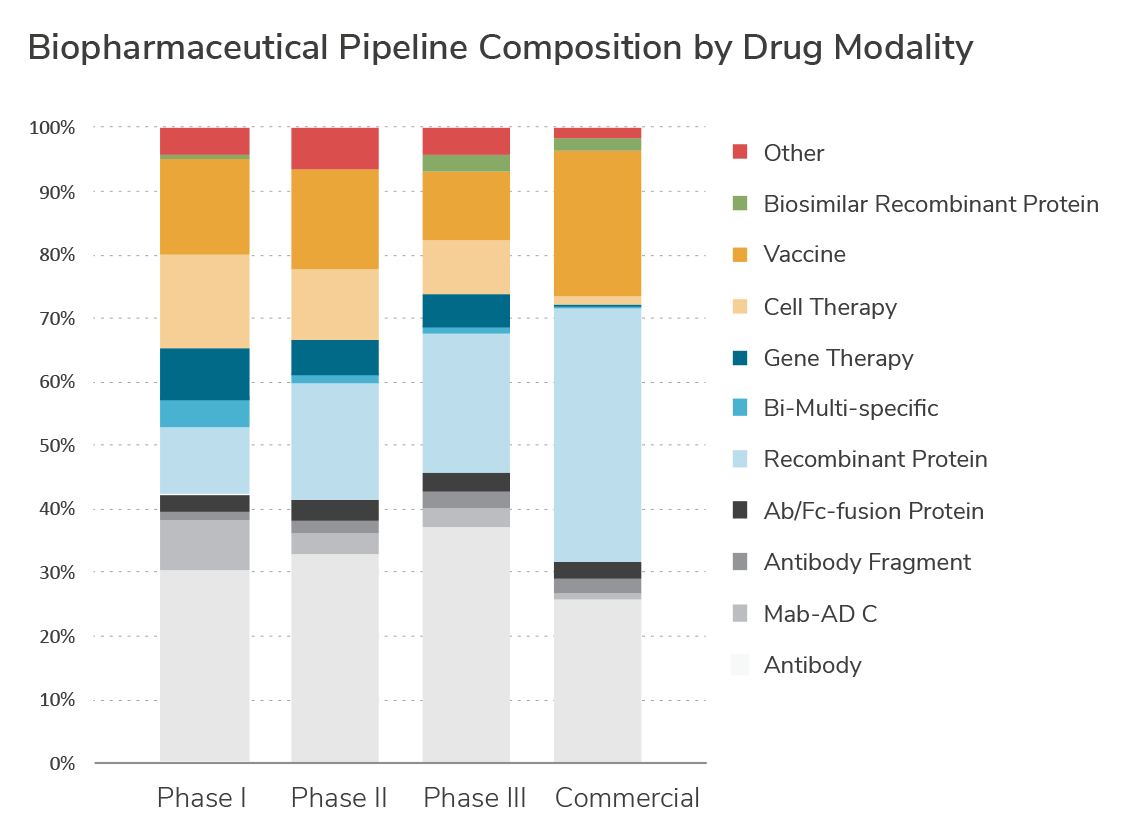

A new generation of purification technologies

Biospecific Antibodies Fc Fusions

Growth Factors, Insulins, Hormones

Recombinant & Viral Vaccines

Gene Therapies

Cell-based Therapies

Product vs. Product-Impurity Separations

Process Analytical Technologies

Affinity resins are affordable – Avitide partnerships have delivered

Providing reliable, consistent, and scalable manufacturing solutions

. . . . . . . . . . . . . . .

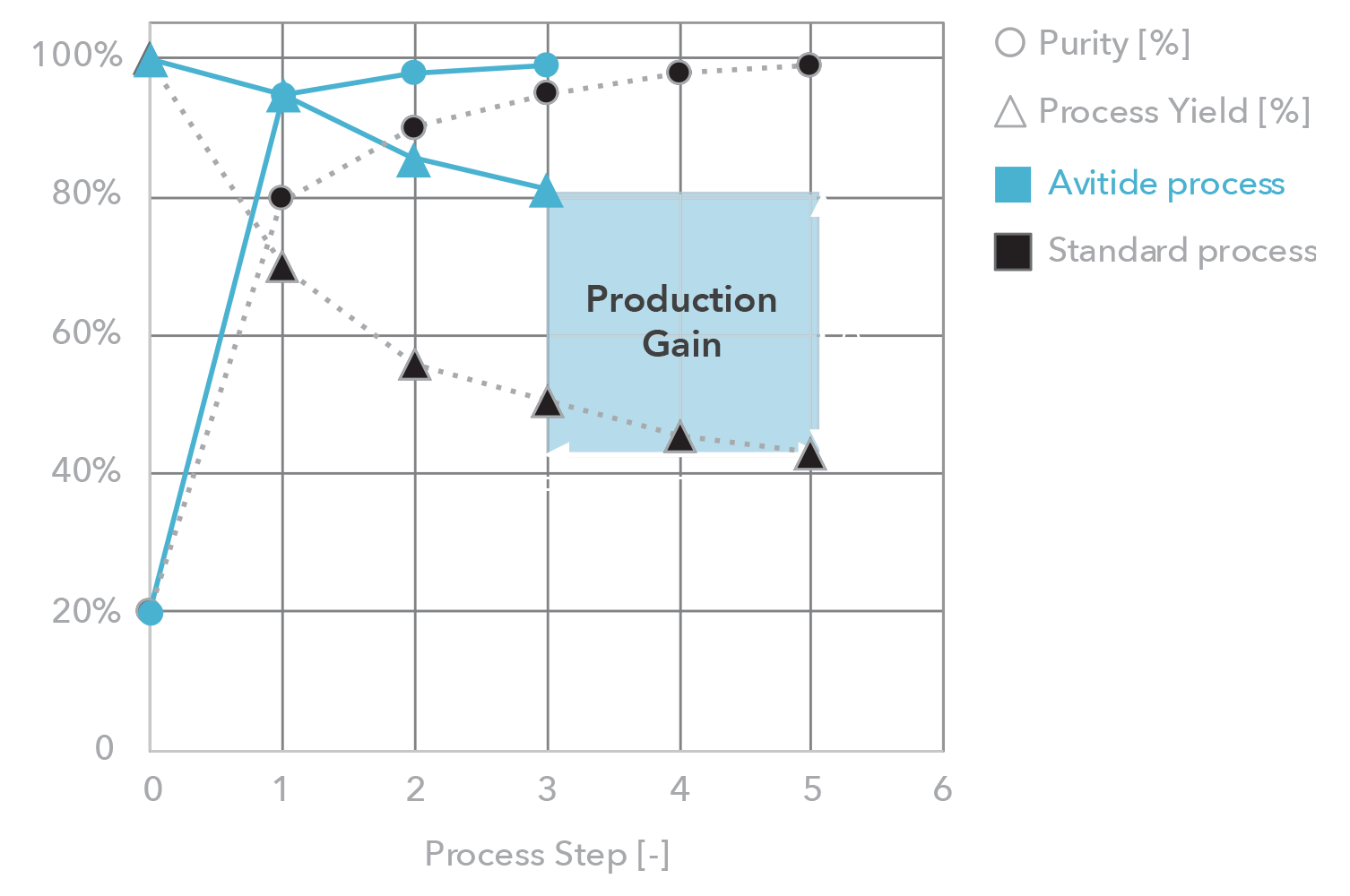

Ensuring purity and yield goals are met early in development

- Derisks commercial manufacturing line of sight

- Increases overall speed of development to reach the clinic and market

- Avoids development challenges commonly encountered with novel therapeutic modalities

- Integrates with CDMO development services

. . . . . . . . . . . . . . .

Improving commercial economic viability and drug accessibility through cost efficiencies

. . . . . . . . . . . . . . .

Expanding exclusive intellectual property around biologics via new manufacturing process patents

. . . . . . . . . . . . . . .

Establishing multi-product facilities with similar operational architecture to antibody production facilities

. . . . . . . . . . . . . . .

Improving overall facility productivity and leverage of existing CAPEX investments

. . . . . . . . . . . . . . .

Enabling fully continuous downstream processing of novel biologic modalities

1-2 yrs

$4-6M

2-8x

2-6x

16 Cavendish Court

Lebanon, NH 03766

603.965.2100

email us

Subscribe to hear the latest news and insights…